Polyester Sling And Types

Polyester lifting slings: Strong, secure, traceless.

what we’re offering

Quality and reliable service worldwide.

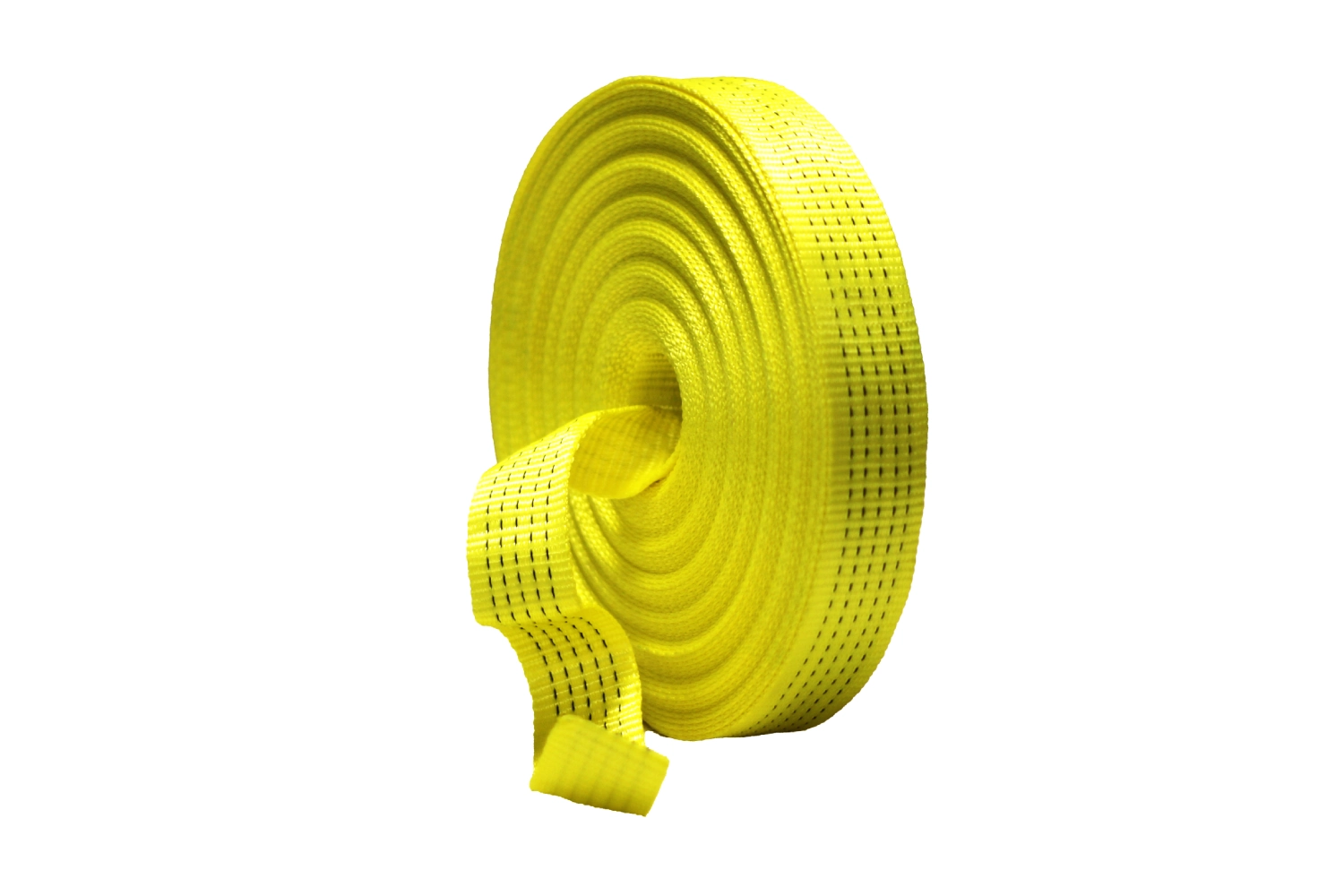

Polyester Slings and Types

Polyester lifting slings are manufactured from 100% high-strength polyester yarn. Polyester slings are widely used in iron and steel, shipping, logistics and transport, oil fields, port management, machinery, etc. Examples of application areas are heavy loading and unloading, product transfer from factory and warehouse areas, cargo securing, towing and recovery operations on ships, machinery and equipment transfer in production.

Polyester lifting slings come in 3 types: duplex webbing, round and endless. Depending on the environment in which the slings are used, you will need to choose the material best suited for your application.

Polyester lifting slings do not damage products and do not leave marks.

General Advace of using Polyester Lifting Slings:

- Make sure that the weight of the load to be lifted is suitable for the lifting capacity of the sling.

- The weight and center of gravity of the load to be lifted must be determined.

- During use, the slings should not be rubbed against sharp and rough surfaces, dragged on the ground, stepped on, or driven over.

- Make sure the label is legible and not torn.

- The slings should be secured to carry the load at their full width.

- It is ABSOLUTELY essential that the hook of the crane is perpendicular to the center of gravity.

- In cases where slings are worn out, deformed, cut, burnt, or in contact with chemicals, they MUST NOT be used.

- Under no circumstances should the sling seams be aligned with the hook area or other lifting devices.

- Slings with knot bends, or repairs should NEVER be used.

- The angle between the sling and the horizontal during lifting is very important. The larger the angle, the lower the lifting capacity of the sling.

- When using more than one sling during lifting, it must be checked whether the slings lift the load evenly and its balance.

- Avoid sudden swinging and jerking movements at all times.

- Never stand under a load when it is being lifted or lowered.

- The load should never be left on the sling for a long time.

- The load should not be slid on the sling when lifting it.

- No one should be present in the work area when lifting the load with the sling.

- Polyester slings should not be used or stored in places where chemical substances or vapors are present.

- If necessary storage conditions are provided, their shelf life should not exceed 5 years.

- The production date of ropes must be checked before use.

- Slings must be allowed to breathe. They should not be exposed to sunlight (ultraviolet radiation)

- Slings should be kept away from flammable materials and high-temperature environments.

- Unused slings should be stored in their package and their certificate should not be removed.

- The carrying capacities of polyester slings are specified with certain colors according to European standards.

- The thickness of the sling should be checked. Great attention should be paid to the carrying surface of the sling. If the material to be carried has rough, sandy, sharp, etc. surfaces, it should be kept in mind that it will have a sanding effect on the surface of the sling while carrying the products.

- When using multi-arm slings, the ends of the sling arms must be connected to the same ring, and care must be taken to ensure that the sling arms are at an appropriate distance.

- When wet, slings should be air-dried naturally, and when dirty, they should be washed and stored dry. Wet slings should be hung in a place to dry by air effect, and should not be dried in a drying machine or under direct sunlight.

- If more than one sling is to be used in applications where one sling is not sufficient for lifting the load, care must be taken to ensure that the raw materials are the same. NEVER lift loads with slings of different characteristics. It is dangerous in terms of work safety.